Waste and Chemicals Management

Habitat And Biodiversity Impacts

Where operations may have an impact on local animal and plant populations, we partner with our customers to create a plan to address this impact prior to the commencement of operations. While many of these impacts are outside of our operational control, we work with our customers to comply with their biodiversity and other policies related to the protection of local wildlife. Many of our areas of operation have substantial wildlife populations, especially during particular months of the year. To mitigate the impacts to wildlife, we have trained employees on best practices for avoiding wildlife vehicle collisions.

Additionally, when operating in sensitive areas, where possible, we have used power from local electric utility grids in place of hydrocarbon fuels to eliminate engine emissions and reduce noise. Our EcoCell technology allows us to eliminate one of the diesel generators on a rig, which can reduce emissions and noise in sensitive areas. We have also consolidated facilities where possible to centralize operations, which reduces our overall footprint.

Waste and Chemicals Management

Under our policies for non-hazardous, hazardous and universal waste generated at jobsites, waste streams are handled, labeled, managed, accumulated, inspected and disposed of in accordance with applicable state and federal regulations, as well as best management practices. Our waste management policies also include procedures for handling new and/or unknown waste streams according to state and federal regulations.

Waste Management Policies

Under our policies for non-hazardous, hazardous and universal waste generated at jobsites, waste streams are handled, labeled, managed, accumulated, inspected and disposed of in accordance with applicable state and federal regulations, as well as best management practices. Our waste management policies also include procedures for handling new and/or unknown waste streams according to state and federal regulations.

Waste Minimization Strategies

We promote waste minimization strategies including recycle and re-use, maintaining the condition of materials, equipment and storage containers, as well as inventory management. Additionally, we adhere to a scheduled maintenance program that is tailored to each type of equipment to reduce unnecessary waste and increase the overall life cycle of our equipment.

Our manufacturing operations use certified waste disposal services for disposal of manufacturing by-products. Our contract drilling and pressure pumping businesses approve and verify vendors for the storage, transport, and disposal of used lubricants at relevant locations and require these vendors to comply with all relevant lubricant disposal regulations. A

dditionally, we continue to increase the use of electronic management systems and documentation, which reduces waste relative to paper-based systems. Our electronic management systems include thousands of pages of documentation, portions of which would otherwise have to be printed out for use, and re-printed upon any revision, on every Company drilling rig, fracturing spread, facility and office. We estimate that our use of electronic management systems has saved hundreds of thousands of pages of paper.

Our pressure pumping business maintains a process for product management that was developed to minimize waste generation. Products that are not used are first remarketed. If we are unable to find a buyer for the product, we attempt to find a recycling provider. If no buyer or recycler is found, the material is properly disposed of according to applicable regulations, utilizing waste brokers to find appropriate recycling and disposal methods for materials identified.

Chemicals Management

Chemicals Management

While we do not develop or manufacture chemicals, we utilize a variety of chemicals in our drilling and pressure pumping operations. Most of this chemical usage is dictated and often purchased by our customers. During 2023, we used 168,586,222 cubic meters of hydraulic fracturing fluid in our completion services operations. This amount includes water, proppant and chemical additives.

Our management system contains a variety of chemical management policies, including policies regarding storage, labeling, HAZCOM (discussed below), transportation, and training. Our supply chain group tests the majority of the chemicals that we purchase using our internal laboratory testing capabilities to ensure that these chemicals meet our needs.

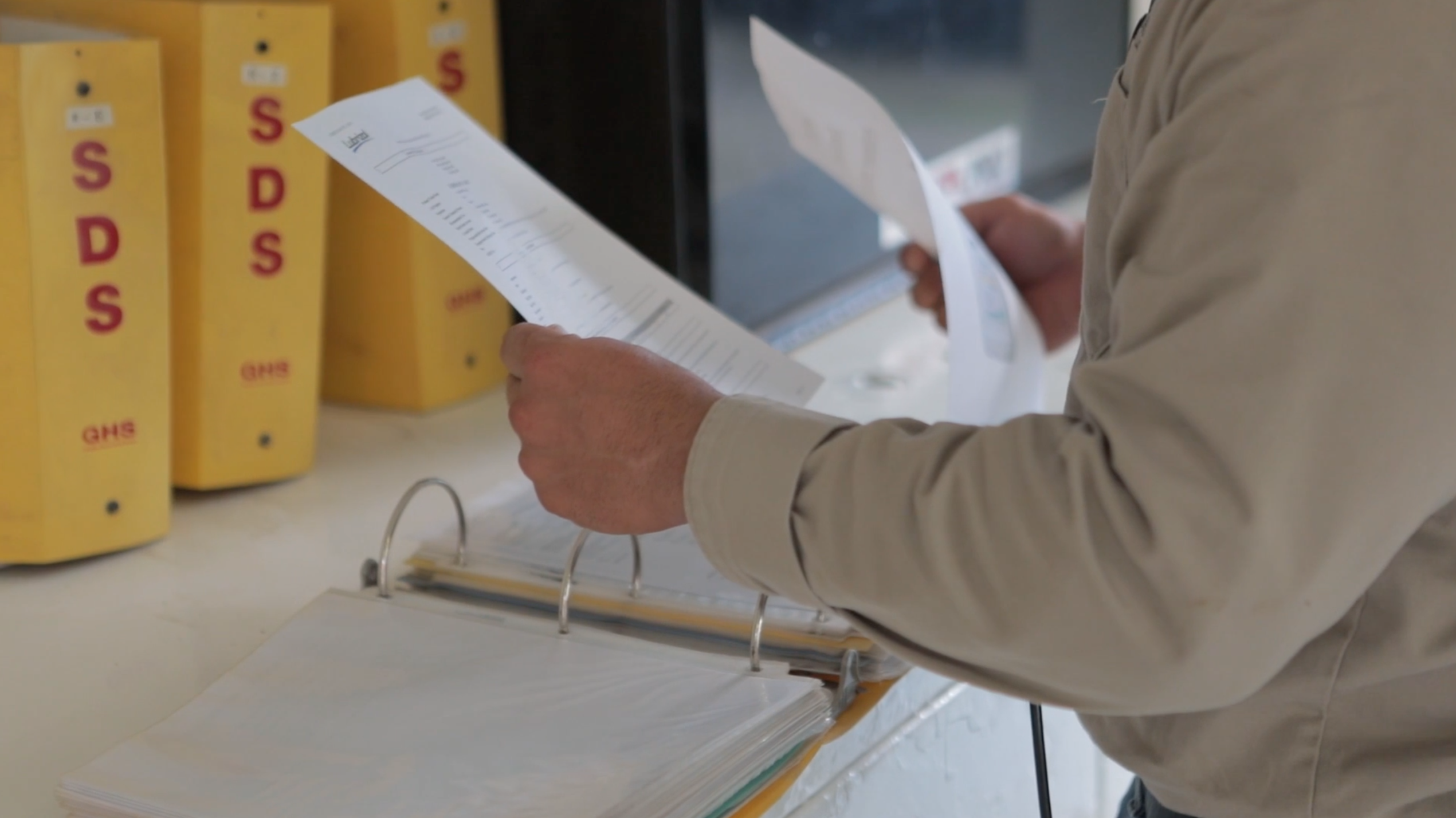

To mitigate chemical risks, we have a comprehensive HAZCOM program in place to classify and relate health information of all chemicals and products used at Patterson-UTI jobsites to all personnel, which includes:

- Safety Data Sheets (SDS) for Patterson-UTI purchased chemicals available in an online database at all our jobsites

- Guidelines to ensure proper container labeling using the Globally Harmonized System (GHS)

- Employee training for all personnel on potentially hazardous chemicals in the workplace

Chemical recycling initiatives are in place whereby a number of our chemical suppliers agree to provide chemicals (for example, lubricants) for use and, once the chemical usage is complete, take away the waste for recycling.

Our Drilling Products segment partners with a third party to provide recycled minerals and materials which are distributed across a variety of industries, including healthcare, energy, construction, automotive, aerospace, technology, agriculture and defense.