Air Quality, Greenhouse Gas Emissions Reduction and Energy Efficiency

Air Quality, Greenhouse Gas Emissions Reduction and Energy Efficiency

We are committed to working with our E&P customers to reduce emissions and maintain a strong environmental performance in all facets of our operations, including the use of innovative fuel product solutions whenever possible. We believe that our capabilities to operate with alternative power sources help differentiate our Company. For many years, we have invested in the deployment of lower-emissions engines and technology in the oilfield, and demand for these emission-reducing engines and technology has increased in recent years.

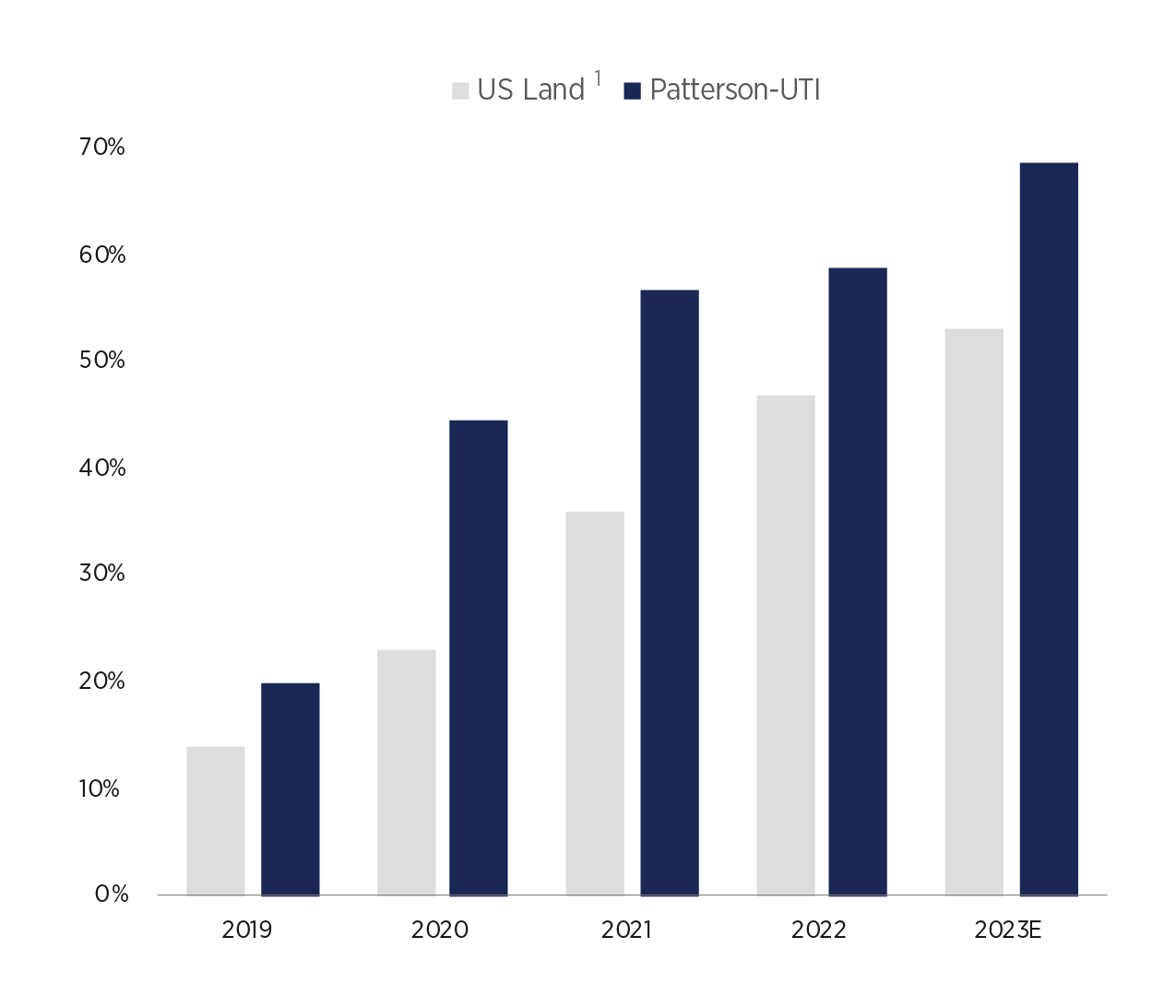

As a service provider, we are dependent on the needs and demands of our customers when determining the composition of our fleet. To help our customers satisfy their own fuel reduction and emissions reduction goals, as well as reduce fuel usage and emissions from our own operations, we plan to continue investing capital to support these efforts. In 2023, 66% of our operating rigs were equipped with alternative power sources such as high-line power from the electric grid, dual fuel or natural gas-powered engines, or our proprietary EcoCell lithium battery hybrid energy management system. We also launched our first electric frac spread in 2023 within our Completion Services business, and we have one of the largest deployed fleets of emissions reducing CAT 351 2E DGBTM Tier 4 engines in the market.

In the short-term, we work to meet customer demands by offering our existing lower-emissions and alternative fuel equipment, such as dual fuel equipment and richburn natural gas engines (in place of traditional dieselonly equipment). In the long-term, we will endeavor to meet these demands by continuing our development of innovative, lower-emissions technology (such as continuing to expand natural gas fueling service and our electric frac spreads, battery power hybrid energy management systems and technology enabling the use of utility electrical power in our operations) and redesigning our equipment to maximize efficiency (such as through the development of emission-reducing automation, remote operations and control systems and energy management software). Our operations include the use of natural gas engines, dual-fuel equipment, and various emissions reduction systems. We utilize equipment that runs on a variety of fuels to improve efficiency and reduce environmental impact. An increasing portion of our contract drilling fleet uses natural gas-only engines and dual fuel engines, and an increasing portion of our pressure pumping fleet uses dual fuel engines.

Innovative Solutions To Power Operations

From natural gas to lithium batteries to natural gas compression or delivery, Patterson-UTI provides sustainable solutions. We have a family of environmentally friendly technologies, designed to reduce emissions and fuel consumption and improve sustainability performance.

- 100% Natural Gas Generators on Drilling Rigs

- Electric Fleet Additions

- Natural Gas Delivery and Handling Solution

- Dual Fuel Frac Spreads and Drilling Rigs

- EcoCell Battery Energy Storage

- High-Line Power

- GridAssist Utility Power Management Softwar

- Automated Engine Management Software

- Natural Gas Compression and Delivery

Natural Gas-Enabled To Lower Cost And Lower Carbon

Our Emerald™ Electric Fleet is able to transition to lower cost, lower carbon fuels at the wellsite.

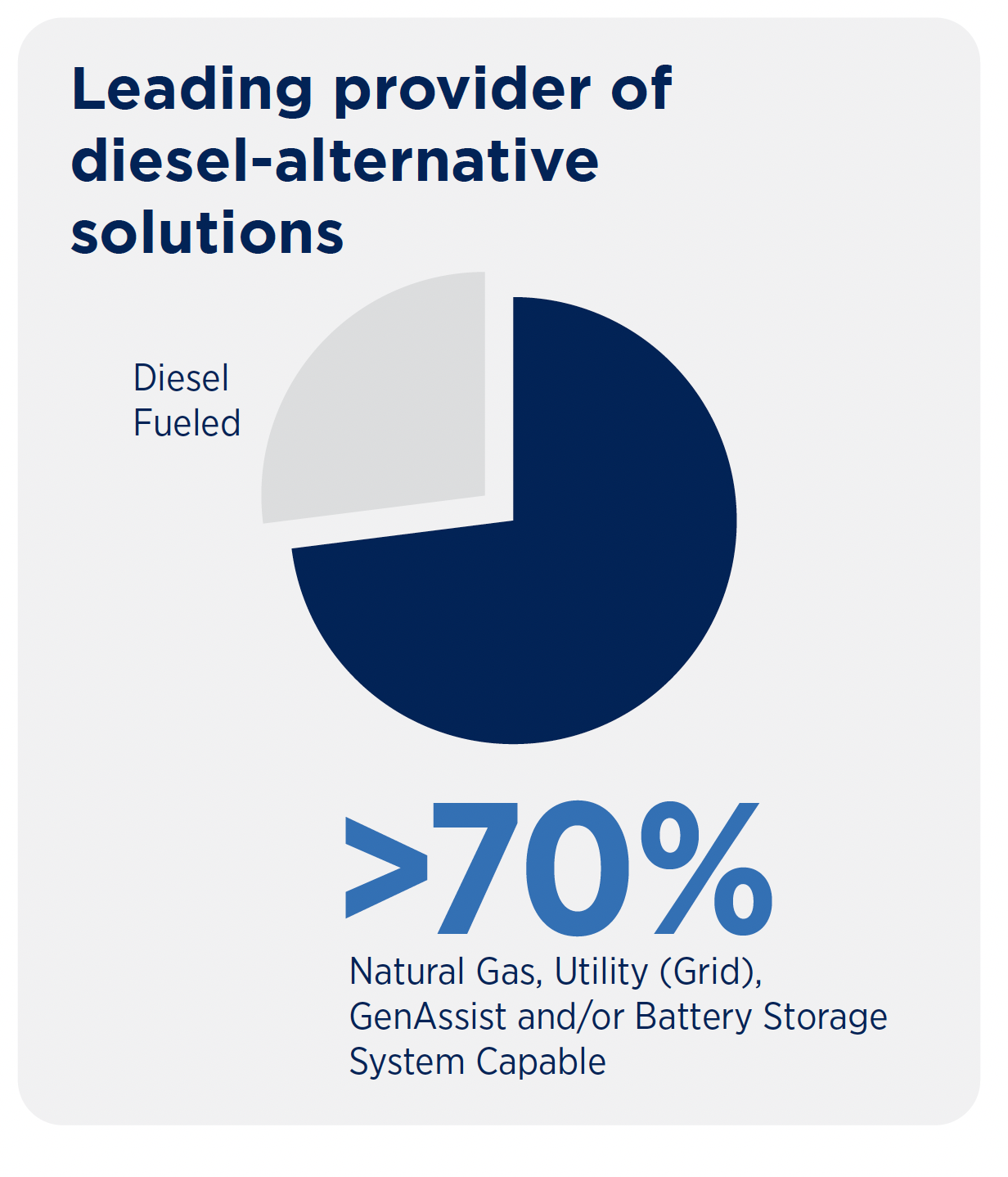

- More than 70% of NexTier’s fleet can be powered by natural gas

- Natural gas-powered fleets can lower annual fuel costs by more than $15 million per fleet2

- Natural gas lowers CO2 emissions by 30% compared to diesel2 Sources: 1NEX Internal Estimates, 2U.S. Energy Information Administration 0%

Emissions Reduction Programs And Innovations

Dual-Fuel Engines

With dual fuel engines, we can offer pressure pumping and contract drilling services with a fuel mixture of up to 70% natural gas. Substitution of cleaner-burning natural gas in place of diesel fuel is significantly better from an environmental perspective, as natural gas generates less carbon monoxide than diesel fuel, as well as less nitrogen oxide (NOx), enabling our engines to burn cleaner and reduce greenhouse gas emissions, which improves air quality.

Within our Completion Services business, more than 70% of our pressure pumping spreads are currently dual fuel capable. Our contract drilling business maintains approximately 69 dual fuel rig power systems.

Natural Gas Engines

We were the first contract driller to use Waukesha natural gas engines on a drilling rig. The rich-burn natural gas engines, which do not require the use of diesel fuel, allow our drilling rigs to run 100% on natural gas. The substitution of natural gas in place of diesel fuel results in a variety of environmental benefits, including emissions reduction.

These natural gas systems have the ability to utilize the local natural gas infrastructure that is often available in our working areas, reducing the need for diesel fuel transportation and consumption. These dedicated natural gas engines are also equipped with a three-way catalyst to significantly reduce NOx emissions.

Third-party field tests on dedicated natural gas drilling rigs have shown emissions of NOx as low as 0.01 g/hp-hr. Our contract drilling business has 15 dedicated natural gas rig power systems, 11 of which were in operation at the end of 2023.

Genassist™ Load-Dependent Starting and Stopping

Our contract drilling business has developed rig automation systems with Load-Dependent Starting and Stopping, which we refer to as GenAssist. GenAssist allows for automatic shut-down of engines when they have been running at low load levels for extended periods of time, and automatic start-up of additional engines when the power capacity levels of engines that are currently operating are exceeded. This feature reduces the amount of time that our engines run at inefficient power levels, thus reducing unnecessary emissions.

GridAssist™ Utility Power Management System

Our contract drilling business deployed our newest proprietary power solution in 2023, designed to enable rigs to utilize utility power in locations where the available utility power is insufficient to support all rig operations. GridAssist prioritizes power consumption from the utility grid and supports demand above the utility limit by leveraging battery energy storage and additional generators if necessary. Our customers can modify the utility import limit on each location as the utility requirements differ. By enabling our customers to use clean power from the grid, GridAssist can drastically reduce generator runtime or completely eliminate the need for generators, resulting in significant reductions in fuel consumption and emissions.

EcoCell™ Energy Storage System

Our contract drilling business utilizes lithium battery technology in our rig fleet through our proprietary EcoCell technology. EcoCell is an energy management system for drilling rigs that uses lithium batteries to store and dispense energy for use in drilling operations. This system stores energy in lithium batteries at times when demand from operations is lower than the rig’s generator capacity and provides supplemental power back to the rig when demand exceeds the rig’s generator capacity. This functionality allows us to maintain a steady and optimized load on the rig’s generators, keeping these generators running in the most efficient range where they produce the lowest emissions levels and best fuel economy. EcoCell has demonstrated the ability to reduce rig fuel consumption by more than 20%, thereby reducing both fuel costs and emissions.

A new zero-generator mode was released in 2023 that enables further reductions in fuel consumption and emissions. This new feature will shut down all generators during low power demand operations and use only battery power, reducing overall generator runtime. This is just one example of many new features as part of the continuous development process to maximize the performance of the product.

At of the end of 2023, EcoCell was deployed at 11 of our drilling rigs, with additional units added in 2024.

Utility Electric or High-Line Power for Drilling Rigs

We are continuing to increase and have invested in additional substations to cover anticipated growth in demand.

Through our Current Power business within Drilling Services, we provide in-house electrical engineering, control system automation and installation services to connect drilling rigs to utility electrical lines. This capability enables our customers to use utility power, instead of natural gas or diesel fuel, to power their drilling operations. we also offer utility power equipment and services for use in industry outside of Patterson-UTI’s drilling rigs.

Using utility power is an optimal power solution on our drilling rigs as it minimizes emission impacts at the wellsite. We have used this technology to connect rigs to utility power in the Permian and Mid-Con basins and expect the use of utility power to continue to increase due to customer demand.

Low Carbon Ventures

We continue to evaluate methods of expanding our existing businesses into offerings that include alternative energy sources and operate with reduced emissions, while continuing to focus on high quality performance for our customers. For example, our Drilling Products business partners with our customers to provide drill bits for geothermal related projects. Our Vice President of Low Carbon Ventures oversees these opportunities and future investments, including technologies in carbon capture and sequestration.

Automation and Remote Operation Systems

Our businesses have developed, and continue to develop, advanced automation and remote operation systems and software. These systems and software allow for increasing automation and remote monitoring of wellsite operations. Many of the locations at which we provide operations are located a long distance from our and our customers’ facilities, resulting in a need for significant vehicular travel.

By improving automation and remote operation capabilities, we can reduce unnecessary vehicular travel to the wellsite by our personnel, thus reducing carbon emissions. The increased use of automation systems and remote monitoring can also reduce the number of personnel at the wellsite, which generally leads to fewer safety incidents.

Our remote operations and real time data centers provide digital intelligence with in-house expertise to optimize job planning, improve efficiency, assist with reporting, and enhance environmental performance. Additionally, expertise through artificial intelligence reduces operational costs, and can minimize on-site wait time and reduce the number of vehicles on the road. These digital centers also help with equipment health monitoring and maintenance.

Tier 4 Fracturing Spreads

We design our drilling and pressure pumping fleets to be 100% compliant with all current EPA air emissions requirements. Additionally, we are sensitive to and supportive of customer climate and emissions-related targets, scenarios and goals. Our Tier 4 compliant engines reduce harmful exhaust gases from diesel powered equipment, and the use of these engines results in significant reductions in emissions (PM and NOx) relative to previous-generation engines.

Our pressure pumping business helps to meet our customers’ GHG emission goals by utilizing our dual fuel and Tier 4 compliant fracturing spreads.

80% of our completion services fleet is natural gas capable.

Additional Fuel Reduction Efforts

We are also able to reduce fuel consumption at the wellsite through our Hibernate™ warm-start system, which gives us the power to turn off pump engines when they are not needed. When the next stage is ready, the crew can remotely restart multiple pump engines from the data van. Hibernate is compatible with both full-diesel and dual fuel fleets, and makes frac sites cleaner, quieter, and more efficient. By eliminating nonproductive engine idling, we accomplish:

- Reduced fuel usage and related emissions

- Decreased load and journey volume

- Decreased equipment wear and required maintenance

- Reduced crew members’ exposure to heavy machinery

- Removed excess noise pollution to improve on-site safety and communication

Particulates (Dust) Control

Our pressure pumping business actively works with its service partners to develop, test and implement new technologies to reduce particulates and dust emissions on location. We currently operate with a combination of active (ventilation systems) and passive (tenting and limiting flow) technologies that significantly reduce dust concentrations. We routinely monitor technologies in use to measure the amount of reduction attained and continually work to reduce emissions and exposures.

Remote Measurement While Drilling

We continue to commercialize our remote measurementwhile- drilling (MWD) services within our directional drilling business. In 2023, our remote MWD services executed services on approximately 180 well sites during the year. Our remote MWD services typically result in a 50% reduction of our MWD personnel at the well site, and in certain instances, have enabled us to perform services without any MWD personnel at the well site. The reduction of personnel at the well site results in reduced overall emissions, including the removal of vehicles from the roadways and decrease of the overall miles traveled.

Other Emiisions Reduction Efforts

Natural Gas Fueling and Delivery Busineess

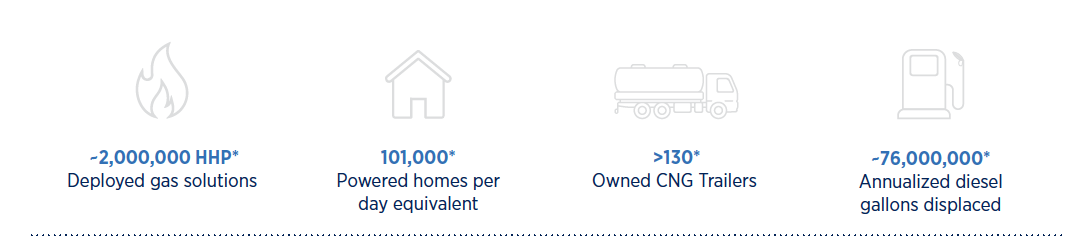

Our natural gas fueling business helps to maximize diesel displacement by helping customers utilize as much of their in-field produced gas as possible, based on availability. When in-field produced gas is not available, we provide compressed natural gas (CNG).

Our natural gas fueling business displaced over 55 million gallons of diesel in 2023, an increase of 162% over the prior year.

We have also invested and committed capital to expand our field gas treatment capabilities and technologies to be deployed in the coming years, equipping our customers to consume even more of their in-field produced gas, which saves costs and reduces delivered truck loads of CNG to the wellsite.

Energy Efficiency

Efficient Use of Energy

We seek to employ energy efficient technologies and reduce energy usage throughout our facilities. Completed and ongoing initiatives include:

- Installing LED lighting on all new and refurbished drilling rigs

- Upgrading lighting in warehouses and shops, including LED lighting

- Converting to LED on all light repair replacements

- Installing motion detection systems that automatically turn off lighting when not in use

- Ongoing review and consolidation of our facility footprint

| ENERGY CONSUMPTION | |

| Fuel Consumption (Off-Road) | 2023 (in gigajoules, rounded) |

| Diesel (1) | |

| Contract Drilling, estimated (2) | 13,589,000 |

| Pressure Pumping, estimated (3) | 21,584,000 |

| Fuel Consumption (On-Road) (4) | |

| Diesel | 746,000 |

| Gasoline | 286,000 |

| Electricity Consumption, estimated (5) | 139,000 |

1. We present off-road fuel consumption for our contract drilling and pressure pumping businesses, as those are our two largest businesses (Drilling and Completion Services constituted approximately 95% of our 2023 revenues), and we believe that the off-road consumption of fuel by these two businesses comprises substantially all of our consolidated off-road fuel consumption.

2. Off-road fuel consumed by our equipment during drilling activities is purchased and controlled by our customers, and they do not provide us the actual levels of fuel consumption (nor the type of fuel used). Accordingly, the fuel data above is based on estimates, which were derived by measuring engine loads and power output for a subset of our drilling operations, calculating related fuel consumption based on published engine parameters, and extrapolating that data to cover the entirety of our annual drilling operations. We have deployed technology that allows us to more frequently and precisely calculate fuel consumption.

3. Off-road fuel consumed by our equipment during pressure pumping is usually purchased and controlled by our customers, in which case they do not provide us the actual levels of fuel consumption (nor the type of fuel used). Accordingly, the fuel data above is based on estimates, which were derived by measuring engine loads for all active engines during the year and calculating fuel consumption based on published engine parameters. As mentioned above under the Vehicle and Engine Idle Time Monitoring section, we have deployed technology that allows us to more frequently and precisely calculate fuel consumption.

4. Total consumption for all Company-owned, on-road vehicles.

5. Electricity consumption data is an estimate of the total electricity usage at our company-owned or leased facilities. We currently have the ability to track actual electricity usage at approximately 95% of our facilities. Accordingly, our total usage presented above includes actual usage data for those tracked facilities, and estimated electricity usage for the remaining facilities. We continue to expand our electricity usage tracking to cover all of our facilities.