Health, Safety and Incident Risk Management

Health, Safety And Incident Risk Management

Consistent with our core value around safety and environment and in support of our overall HSE policies, we launched LiveSafe™ across all of our businesses. LiveSafe focuses our attention and actions on making safety personal in everything that we do, whether on or off the job. We are committed to LiveSafe because we value the safety of our people, our families, and our co-workers.

The safety and well-being of our employees and the protection of our environment are cornerstones, and we are committed to providing a safe, incident-free work environment for all. As stated in our HSE Policy Statement, which applies across our Company, and at all facilities and locations, our managers and supervisors are accountable for the safety of our people and are committed to ensuring that they have functional equipment, required personal protection equipment (PPE) and training for their tasks. We have developed Health, Safety and Environment management systems toestablish the policies, standards, and procedural requirements by which we conduct our business in order to achieve these objectives. We prioritize health, safety, and environmental control and carefully monitor our performance and adherence to established management system requirements. Our executive management and Board of Directors regularly review and discuss, on at least a quarterly basis, our safety results and trends at the beginning of each regular Board meeting.

We regularly audit and review our HSE performance in all of our businesses. The timing and frequency of these audits is set by an established audit calendar, which is developed considering the type of audit and required frequency. Corrective actions are identified and implemented for any non-conformities observed during the audit. Best practices discovered during these audits and other assurance activities are aggregated and disseminated to our operations teams, HSE professionals, and technical services group so they can be reviewed and implemented across our organization.

Safety and Environment

The safety and well-being of our employees and the protection of our environment is a cornerstone, and we are committed to providing a safe, incident-free work environment for all.

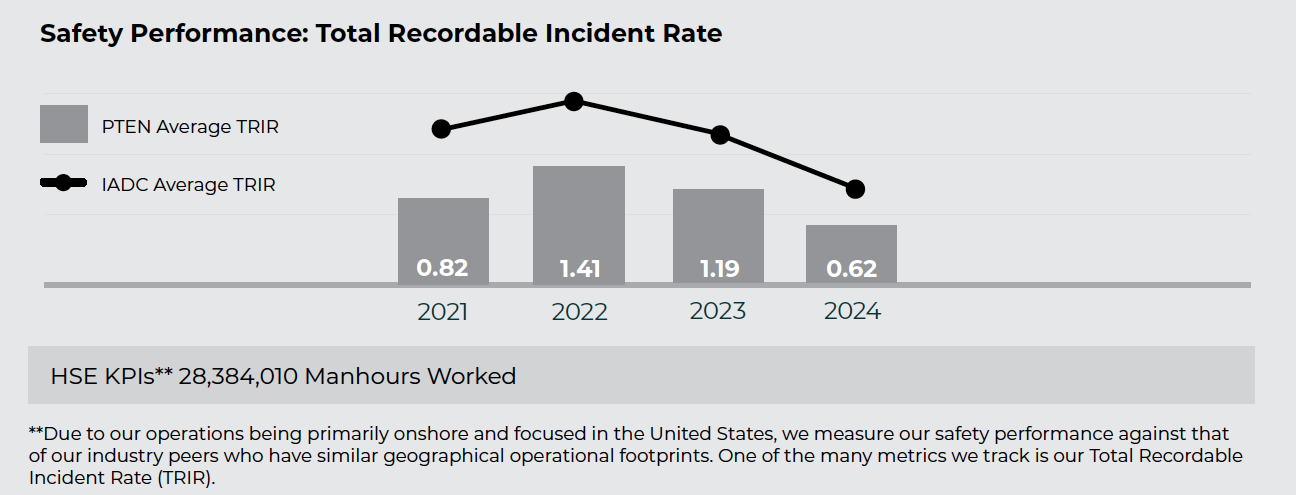

Total Recordable Incident Rate

Ongoing Safety Training

At Patterson-UTI, we prioritize investing in training our employees to be knowledgeable about and responsible for the safe execution of their actions in order to protect themselves, their team members and others. Learning is a core focus and continuous development is a key tenet of our training. Our training programs, both classroom-based and on-the-job, provide our people a clear path for success right from the start. We coach and we mentor. Continuous learning is our way of life.

Risk Management | Stop Work Authority

Stop work authority is focused on stopping the job before something is able to escalate and can no Stop Work Authority is focused on stopping the job before something is able to escalate and can no longer be controlled, potentially resulting in a significant incident or injury. When stop work authority is utilized, a conversation is held with involved personnel to talk about why it was called, what has changed, and what needs to be modified so work can safely resume.

All of our businesses empower employees with stop work authority. We believe there is no job worth performing if it cannot be performed safely. Safety meetings and briefings are tools we use to identify risks and communicate those risks through safety alerts and bulletins.

Pre-Job Assessments

Our Permission to Work program is a formal system of control for all contract drilling operations, focusing on controlling critical and potentially hazardous operations and outlines the requirements for the Jobsite Manager’s permission to control the job rather than a permit. Each job task is categorized based on a risk assessment associated with the expected scope of work, hazard associated with the job and the appropriate amount of supervision required.

Our Jobsite Manager then verifies the work is ready to begin and gives permission for the job to start by signing the certificate. After completion of the work, the Jobsite Manager must conduct a postjob examination of the worksite, close the operation by signing the certificate and conduct a post-job review.

Similarly, our Completion Services business follows its PAUSE process, which includes pre-job checklists and job safety analyses before beginning a job. Completing the PAUSE process and hazard assessment is the responsibility of the Jobsite Manager to help ensure incident-free operations and is required to be completed prior to engaging in any task.

The goal of these programs is to help us to control the outcome of each job in a safe, efficient manner. Additionally, our system dictates that an appropriate level of risk assessment be completed prior to performing any operation, and dynamic risk assessment be conducted throughout the operation.

Employee Safety Orientation

We require all field-based employees to complete Employee Safety Orientation (ESO). Courses include content on Behavior-Based Safety, Hazard Awareness, Safe Systems of Work, Permission to Work, Time Out for Safety, Energy Isolation, HAZCOM, Material Handling, etc.

ISO Certifications

ISO 9001 | ISO 14001 | ISO 45001 Maintained by our Drilling Products business depending on the facility and the work performed.

Driving Safety

The Completion Services business utilizes advanced driver assistance system technology coupled with internal management processes through Samsara, a fleet monitoring system. Samsara offers real time warnings to drivers and gives the Company behavioral reports that monitor driving behaviors, such as speeding, quick turns and accelerations as well as alerting the appropriate leadership and support parties for performance management.

DriveSafe™

Our commitment to safety is reflected in our core values and is a key reason behind why we launched LiveSafe. DriveSafe is the next step in fostering our commitment to LiveSafe principles and our core values.

Maintaining Our Standards

In our Drilling and Completion Services businesses, we routinely evaluate contractors to ensure they meet both Patterson-UTI and our customers’ HSE requirements. In our evaluation process, we review and assess contractors prior to hire based on HSE performance statistics, selected HSE policies and procedures, questionnaires, and third-party evaluation systems. This evaluation process assists us in screening contractors and maintaining our standards. We monitor existing contractors’ safety performance in assessing whether to continue contractor relationships.

HSE Incident Management System

During 2024, we completed the first phase of our new HSE system software platform. This system provides a comprehensive digital platform to manage key safety and compliance processes, including incident management (reporting, investigation, and actions), jobsite engagements (behavior-based safety and stop work), audits, and inspections as well as implements corrective action where needed.

In the areas of audits and inspections, this system offers configurable tools to plan, schedule, and conduct both internal and external audits and site inspections and improve consistency with reporting.

Emergency Planning and Response

In 2024, we also focused on Enterprise Response Plan (ERP) development and implementation, including response requirements for key risks and delineation of responders according to severity of emergency from our local area(s), cascading up through enterpriselevel responsibility. As severe weather is one of the primary risk categories, we also undertook a significant effort to identify, review, and procure weather forecasting services with dynamic monitoring for our key operational centers. This will allow for more timely and focused alerts and activation of response plans.

Jobsite Engagements

We undertook a continual improvement effort for our Stop Work / Time Out For Safety observations to incorporate behavior-based safety observations and leadership engagement visits under our new Jobsite Engagement framework, which is focused on a more integrated and proactive safety management approach.

By incorporating leadership engagement visits, we facilitated structured interactions between leadership at all levels and frontline personnel, enabling direct observation of work practices, assessment of safety compliance, and real-time feedback. These additional engagements serve not only to identify unsafe conditions or behaviors but also to reinforce organizational safety requirements, model safety leadership behaviors, and strengthen communication channels.

By systematically capturing, analyzing, and acting upon data from stop work / TOFS interventions, leadership visits, and safety observations, we are more readily able to identify trends, address underlying causes, and implement targeted interventions to mitigate risk.

Industrial Hygiene Management Policy

We understand the importance of occupational health, as our employees work in many different environments and conditions. We assess these conditions with industrial hygiene management policies that include: respiratory protection, hearing protection, HAZCOM, climate and environmental condition risk mitigation and industrial hygiene monitoring.

We perform industrial hygiene monitoring to identify, evaluate, and document potential exposure to biological, chemical, and physical hazards at our jobsites and facilities, which includes:

- Workplace hazard assessments conducted at each yard, shop and rig location

- Crew houses monitored and inspected on a periodic basis

- Periodic occupational exposure monitoring

- Temperature monitoring on location

Management System, Feedback and Digitalization

We expect our Drilling Services employees to actively participate in crafting our processes and procedures, and we encourage everyone to approach their supervisor with suggestions for improvement and, in our contract drilling business, to use our readily available computer-based feedback system.

Our Management System houses the policies, procedures, and standards that define the Company’s expectations and requirements related to safety and operational processes. The Management System also includes technical standards, forms, inspections, audits and other supporting documentation for daily operations. Our employees have the opportunity to provide direct feedback and suggestions using our Policy Improvement Request (PIR) process. If there is a need for clarification, revision, or the expansion of existing processes, employees can submit their requests through this online system.

Management of Change

Our Management of Change policy provides a managed systematic approach designed to ensure, to the extent possible, that health, safety, and environmental risks are identified, understood, communicated, controlled, and approved prior to implementing certain changes to our operating procedures and policies. The policy requires that certain operating procedural changes be reviewed and approved before implementation to reduce the potential for risks resulting from such changes.

Cornerstones for Life

The “Cornerstone for Life” rules provide our employees with extra focus on potentially high-risk activities where we believe failure to follow rules could lead to a much higher probability of serious injury or fatality.

Cornerstones for Life are tailored for our Drilling Services and Completion Services businesses to highlight critical safety expectations at all jobsites. Patterson-UTI employees, contractors and visitors are required to adhere to these rules. Some examples of Cornerstones for Life in our businesses include:

- Utilize our permission to work process without fail.

- Follow our fall protection policy.

- Properly isolate energy to equipment / lockout tagout when appropriate.

- Follow appropriate management of change protocols.

- Take appropriate precautions when working around overhead power lines.

- Ensure that appropriately sized tubular handling equipment is utilized.

- Follow our safe driving and fit for duty policies.